Professional Pool and Hot Tub Wiring for Safe Outdoor Use

Pools and hot tubs require specialized electrical systems. Improper wiring can cause shock hazards, equipment damage, or system failure. These risks increase when safety standards are not followed. Our pool and hot tub wiring services are designed to ensure safety and performance. We install and upgrade electrical systems that meet strict safety requirements.

Our Pool & Hot Tub Wiring Services

We provide complete electrical wiring services for pools and hot tubs. Each service is completed using approved materials and professional safety practices.

Pool Electrical Wiring Installation

Hot Tub Wiring & Power Connections

GFCI Protection Installation

Pool and Spa Lighting Wiring

Grounding and Bonding for Pools

Electrical System Upgrades for Pools

Why Pool and Hot Tub Wiring Matters

Pool and hot tub systems operate near water at all times. Electrical mistakes can lead to serious injury or equipment damage.

Professional wiring ensures safe power delivery and code compliance. It protects people, property, and valuable pool equipment.

- Improves Electrical Safety: Proper wiring reduces the risk of shock and electrocution.

- Protects Equipment: Stable power prevents damage to pumps and heaters.

- Ensures Code Compliance: Professional work meets electrical safety standards.

- Supports Reliable Operation: Systems run smoothly without interruptions.

- Enhances Outdoor Enjoyment: Safe wiring enables worry-free use of the pool and spa.

Our Pool & Hot Tub Wiring Process

We follow a structured process to deliver safe, efficient, and long-lasting electrical solutions.

We carefully inspect the pool or hot tub area. This identifies wiring needs, safety concerns, and equipment requirements.

We calculate power needs for pumps, heaters, and lighting. Proper planning prevents overloads and system failures.

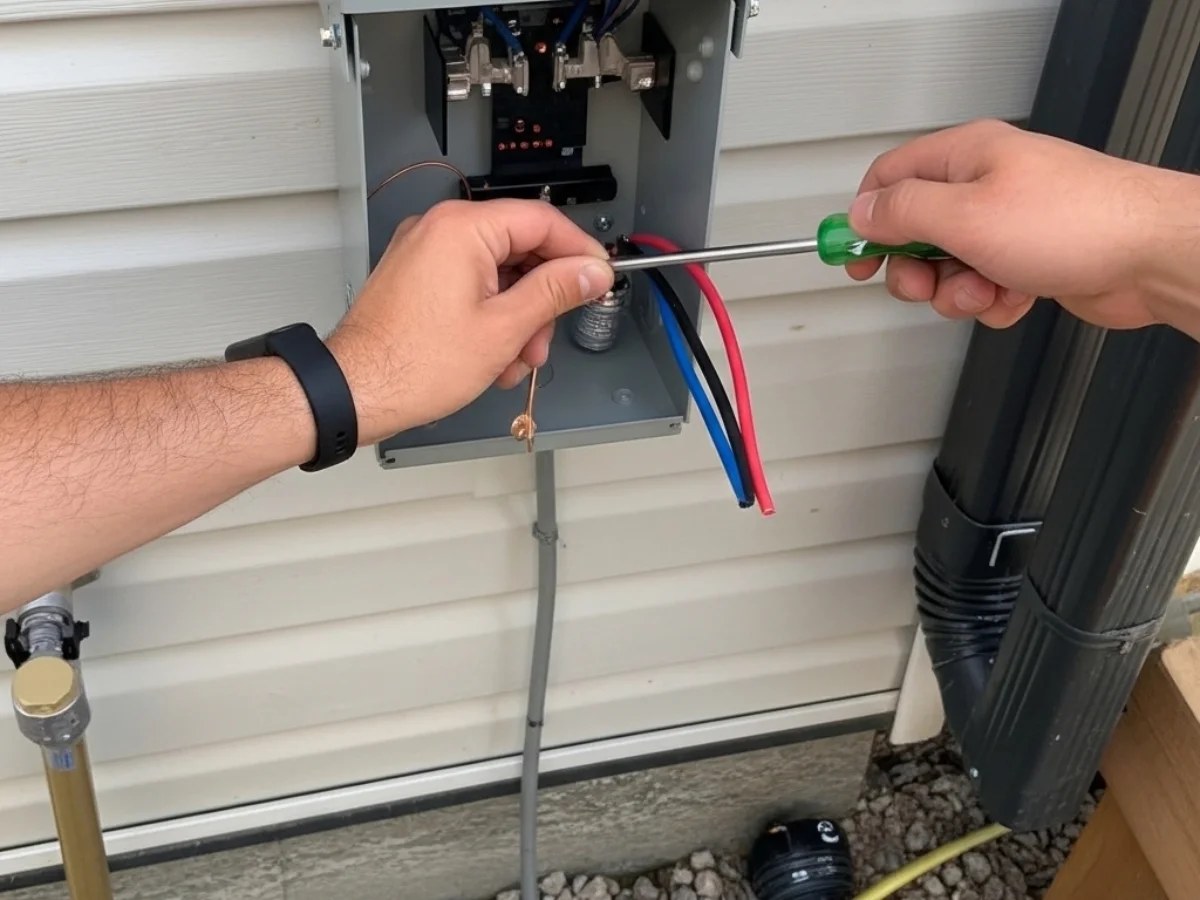

Wiring is installed using waterproof and approved materials. All connections are secured and protected from moisture.

We install GFCI outlets and safety devices properly. These components protect users from electrical faults.

All circuits and connections are tested thoroughly. This ensures proper grounding, bonding, and safe operation.

We clean the area and review system operation with you. Safety tips and maintenance guidance are provided clearly.

Why Choose Us for Pool & Hot Tub Wiring

Licensed & Certified Electricians

Our electricians are fully licensed and trained in outdoor electrical systems. All work follows safety and code requirements.

Water-Safe Electrical Materials

We use moisture-resistant wiring and approved components. Materials are designed for outdoor and wet environments.

Transparent Communication

We clearly explain the process, timelines, and safety measures. You stay informed throughout the project.

Customized Outdoor Electrical Solutions

Each pool and hot tub setup is different. Wiring solutions are tailored to layout and equipment needs.

Clean & Respectful Work

We protect surrounding surfaces and landscaping. The work area is left clean and safe.

Reliable Customer Support

We provide dependable support before and after service. Questions and concerns are handled promptly.

Client Reviews

Ready to Wire Your Pool or Hot Tub Safely?

Pool and hot tub wiring requires expert handling and strict safety standards. Professional wiring ensures safe operation and long-term reliability.

Contact us today to schedule pool or hot tub wiring services. Enjoy peace of mind, safe power, and expert electrical workmanship.

Frequently Asked Questions

Yes. Pools and hot tubs require dedicated circuits and safety components. This prevents electrical hazards near water.

GFCI protection shuts off power during faults. It reduces the risk of electric shock around wet areas.

Sometimes. Older panels may need upgrades to handle the added load. An inspection determines capacity needs.

Yes. Grounding and bonding are required for safety. They prevent shock and stabilize electrical systems.

Most installations take one to two days. Complexity and equipment size affect the timeline.

Yes. Proper installation meets manufacturer requirements. This helps protect equipment warranties and long-term performance.